is an ultra-high stiffness net independently developed by Kinoshita Fishing Net.

is an ultra-high stiffness net independently developed by Kinoshita Fishing Net.

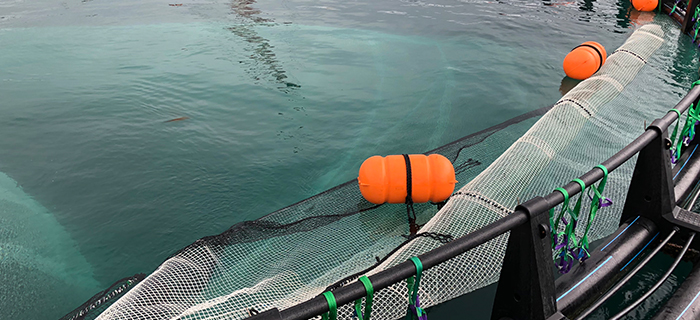

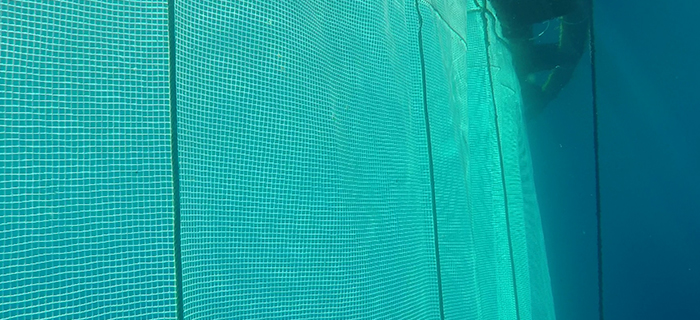

Usage for fisheries (a fish cage, a set net etc.) and land (safety nets and engineering

construction field).

materialMaterial: Polyester 100%

is the patented product of Kinoshita Fishing Net.

is the patented product of Kinoshita Fishing Net.

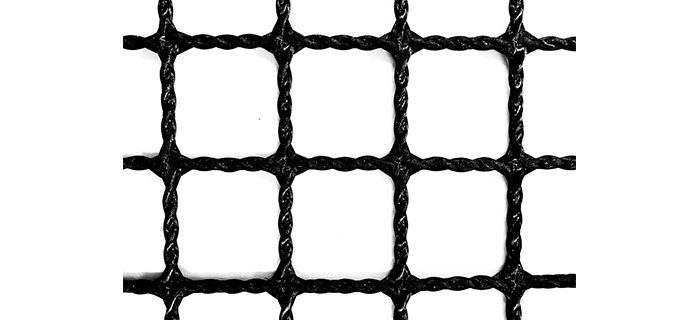

This product does not contain Resin or chemicals. It is a square net heat-treated degree at 170-180℃. The mesh surface is plasticized, so it has high friction and cutting resistance. The fusion of the intersection makes it excellent for maintaining shape even if pressure is applied on it. It is also highly resistant to grease and chemicals. It is easy to clean or maintain. This panel shape makes it easy to process and allows to design easily.

Technical features

■Ultra-high stiffness

■Strong

- *Friction

- *Cut

- *Tear

- *Bending

- *Torsion

- *Chemical Products

- *Current

■Always Square Mesh

■Easy

- *Cleaning

- *Maintenance

■Free Design

- *Mesh Size

- *Thickness of Mesh

- *3 Dimension

- *Assembly

Know-how of stiffness

After conducting several tests in the overseas market, this product earned a good reputation. The part of intersection is firm enough to be called as a forever square mesh. It is easy to clean because seaweed dose not stick well on it. It is plasticized by melting only the surface of ultrafine fibers- filament, by processing with high temperature. The core is still a fiber state, so it does not break even when it is being bent.

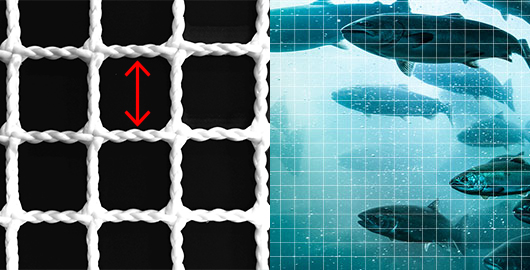

How to determine the mesh size

Considering the safety, choose 50% or less of the object size, the cross-section area, when determining the mesh size. Mesh size indicates the length between the upper edge and lower edge of the inside a square mesh.

Strength of netting twine

※Please inquire for other number of PLY

| Twine Dia. | Number of PLY | B/S |

|---|---|---|

| 2.1mm | 96-ply | 640N |

| 2.3mm | 144-ply | 1100N |

| 2.8mm | 192-ply | 1400N |

| 3.0mm | 216-ply | 1600N |

| 3.3mm | 240-ply | 1750N |

| 4.3mm | 288-ply | 2000N |

| 5.1mm | 384-ply | 2800N |

Including some theoretical values

How to assemble

is shipped with the size of 1.4m~2.1m in width and 30m~60m in length.

is shipped with the size of 1.4m~2.1m in width and 30m~60m in length.

Please draw an assembling drawing: Floor plan and Three-dimensional drawing

- checkHow to cut the panels

- checkThree-dimensional panel layout

- checkThe number of required meters and rolls

- checkProduct cutting (without waste)

Please use rope, finishing threads, clips for assembling

Please select the assembly location

- checkCompleted at the assembly plant

- checkAssembled by parts at the assembly plant and completed on site

- checkPacking method, Transportation method

assembly factory (Vietnam)

assembly factory (Vietnam)

Of course, customers can assembly K-GRID by themselves, but we also undertake it at our partner factory in Vietnam, so please contact us.

How to install

-

Transportation method

Truck, trailer, container, open top container, lift, barge, etc.

-

Installation method / procedure

Unloading, conveyance, installation, secure safety, etc.

-

Required equipment and materials

・Lift, hoists, boats, etc.

・Rope, wire, hook, etc.

・Floats, pulleys, anchors, nails, bolts, fastening plates

Maintenance and refurbishment planning

Cleaning plan:This product is made of 100% polyester.High pressure water-jet simply can remove contamination such as seaweed, shellfish, oil-lubricating oil, animal debris, chemicals, etc.

Well-suited for cleaning robots.

ReassemblyThis product’s surface is a low melting copolymerized polyester and its core is a high-viscosity polyester. This surface is plasticized with high temperature processing. This has a characteristic to withstand changes by the external natural environment and it is particularly resistant to UV rays, so it has been reported that there has been little changed in physical properties even if it has been used for more than 10 years according to the field test of yarn maker. Therefore, even though it is a new product, it is expected to be constant use for over 10 to 15 years.

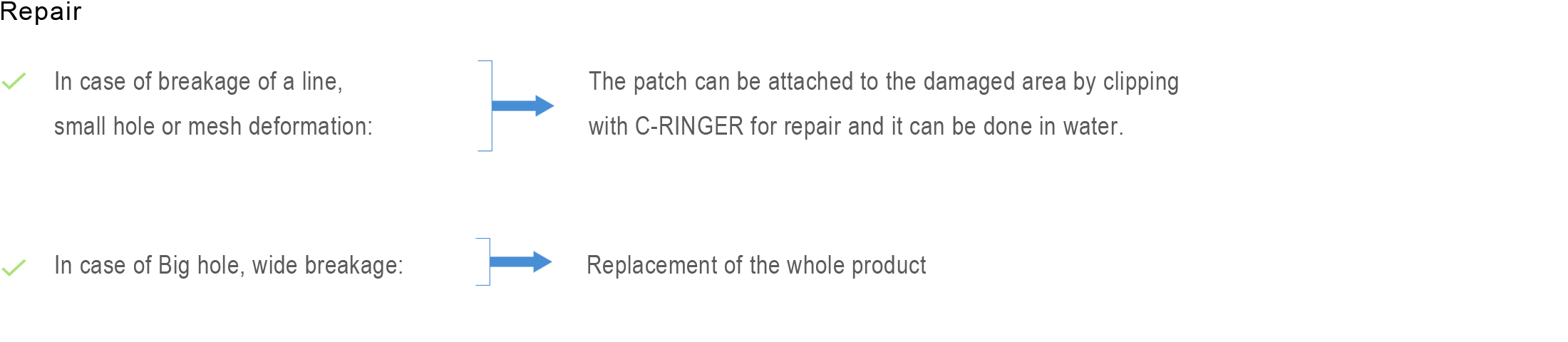

C Ringer

It can be used in seawater.

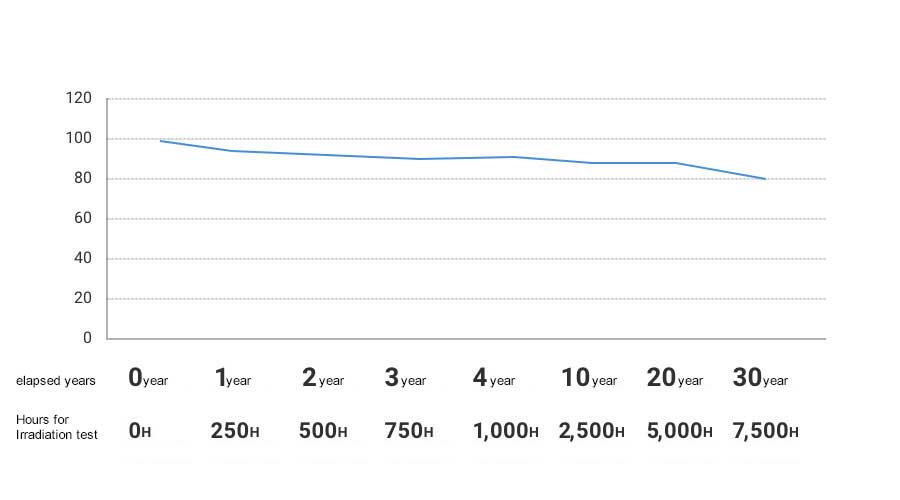

Strength reduction test report by ultraviolet rays

Weatherability test by yarn maker had been conducted with the Sunshine Wadermeter method. See the data on the right. UV Irradiation test had been conducted during 1 year with 250 hours. 7500 hours test conducted- equivalent to 30 years. The test proved that it maintained the strength of 90% or more even after more than 20 years.

Usage record

Australia, Chile, South Korea, Canada, Greece, Turkey and Japan

Service and product inquiry

木下製網株式会社kinoshita fishing net mfg.co.,ltd.

- arrow_forwardHeadquarters/ Plant

- Harimakaito 1, Nishihazu-cho,Nishio-shi, Aichi, Japan 444-0703

- arrow_forwardOsaka office

- Tetsutani Building 601, Tokui-machi 2-2-2, Chuo-ku, Osaka-shi, Osaka, Japan 540-0025

- arrow_forwardYanagawa Plant

- 135-1 Yamatomachi Toyahara, Yanagawa, Fukuoka, Japan 839-0242

- arrow_forwardIshinomaki Plant

- Shinnuma-84, Watanoha, Ishinomaki, Miyagi, Japan 986-2135